Many people use DC motors but might not understand the core differences between them. This lack of clear understanding can lead to choosing the wrong motor for a task. I will explain these two types simply, helping you grasp their basic concepts.

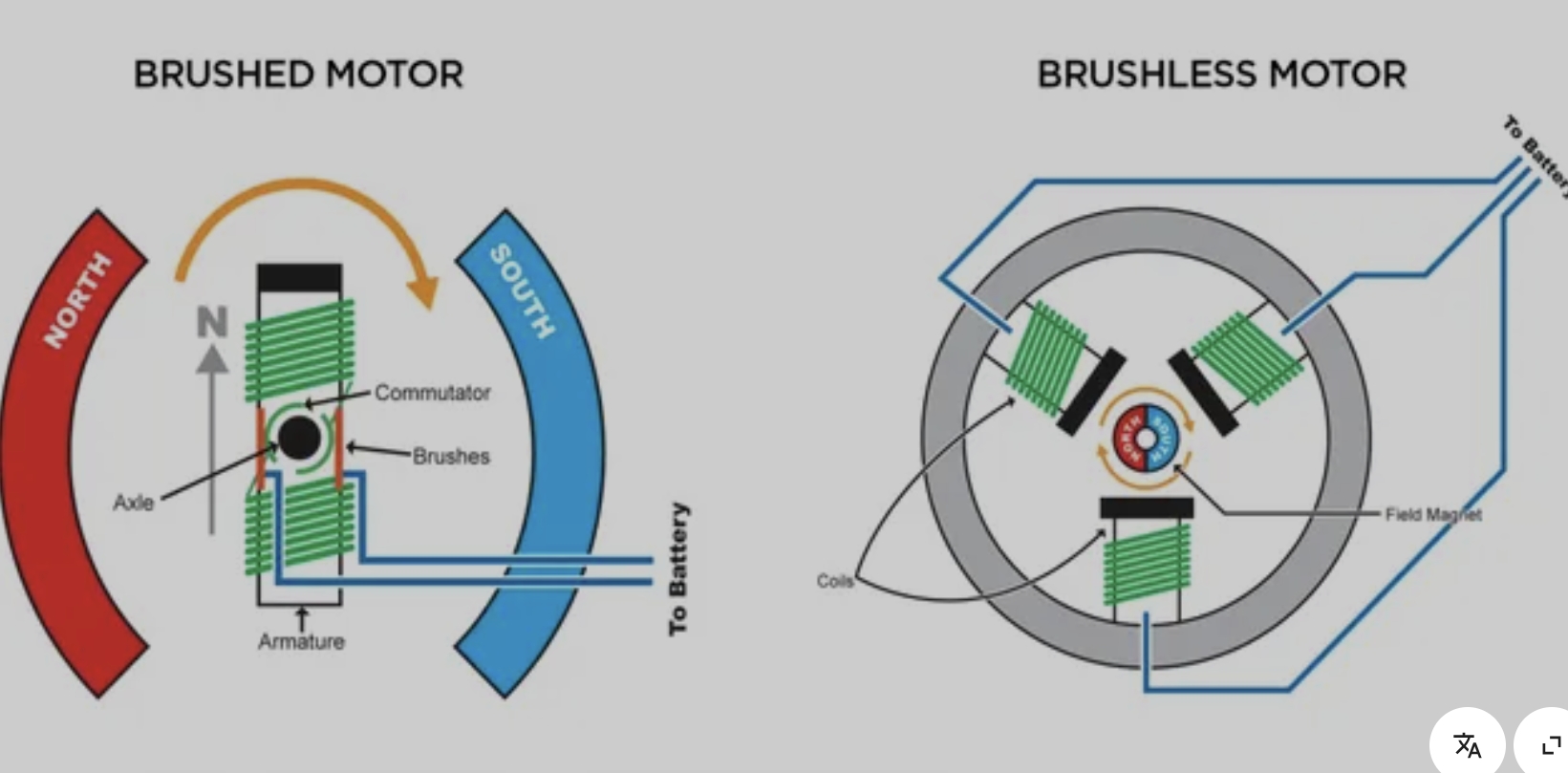

Brushed DC motors use physical brushes and a commutator to reverse current, making the motor spin. Brushless DC motors, on the other hand, use electronic controllers to manage current switching, relying on permanent magnets and electromagnets without any brushes.

Understanding the fundamental way each motor works is important. It helps you see why they behave differently. This knowledge is key when you need to pick a motor for a specific job or fix one that is not working right.

Which is Better, Brushed or Brushless DC Motor?

Deciding between a brushed and brushless DC motor often feels hard. Each type has its own set of pros and cons. I will help you pick the right one for your specific needs.

Neither brushed nor brushless DC motors are inherently "better"; their suitability depends on the application. Brushed motors are typically more affordable and simpler in design. Brushless motors offer higher efficiency, a longer operational life, and quieter performance.

When you choose a motor, you need to think about many things. You must consider what you need the motor to do. I remember a time when I had to pick a motor for a robot arm. I first thought that the newest, most advanced motor would be best. But after looking at the requirements, I realized that a simpler, cheaper brushed motor was actually perfect for that task. It did not need very high precision or a super long lifespan.

Brushed DC Motors: Advantages and Disadvantages

Brushed DC motors are simple. They are also cost-effective. They are easy to control for speed. This makes them good for basic tasks. They are often found in toys or smaller appliances. The brushes, however, wear out over time. They create friction and heat. This means they need more maintenance. They also make electrical noise. This can be a problem for some sensitive electronic devices. Their efficiency is lower than brushless motors. They lose energy as heat through the brushes.

| Feature | Brushed DC Motor |

|---|---|

| Cost | Lower |

| Complexity | Simple |

| Efficiency | Lower |

| Lifespan | Shorter (due to wear) |

| Noise (electrical) | Higher |

| Maintenance | Higher (brush replacement) |

| Speed Control | Easy |

Brushless DC Motors: Advantages and Disadvantages

Brushless DC motors are more complex. They need an electronic controller to work. This makes them more expensive. But they are much more efficient. They run cooler. They last much longer because there are no brushes to wear out. They also make less noise. This makes them good for things that need to be quiet or precise. Examples include drones or electric vehicles. They offer very precise speed control. This is important for high-performance applications. The extra cost is often worth it for these benefits.

| Feature | Brushless DC Motor |

|---|---|

| Cost | Higher |

| Complexity | More complex (needs controller) |

| Efficiency | Higher |

| Lifespan | Longer |

| Noise (electrical) | Lower |

| Maintenance | Lower |

| Speed Control | Precise |

How to Tell if a DC Motor is Brushed or Brushless?

You might have a motor but do not know if it is brushed or brushless. Knowing the type helps with maintenance or when you need to buy a replacement part. I will show you easy ways to identify them.

You can often tell if a DC motor is brushed or brushless by looking for visible brushes or commutator slots. Brushed motors have these external features. Brushless motors usually have a smoother exterior and might have more wires. Checking the motor’s specification sheet is also a reliable way.

Identifying a DC motor’s type is not always obvious at first glance. However, once you know what to look for, it becomes much simpler. I once had a project where I inherited an old motor from a scrapped machine. I had no idea what kind of motor it was. Knowing the different features of each type helped me figure it out fast. This saved me from using the wrong power supply or controller.

Visual Inspection

The easiest way to tell is to look at the motor’s outside. A brushed DC motor usually has small openings or vents. You might see small, carbon blocks inside these openings. These are the brushes. You can also see the commutator, which looks like copper segments. These parts are unique to brushed motors. Brushless motors usually look cleaner and smoother on the outside. They do not have these visible parts. They are often sealed to protect the internal electronics.

Wire Count and Connection

Another clue is the number of wires coming out of the motor. Brushed DC motors typically have two wires. One is for positive power, and the other is for negative power. This is because they take power directly to the brushes. Brushless DC motors usually have three or more wires. These wires connect to the motor’s coils. The extra wires are for phases or for sensors that tell the controller where the motor is positioned. If you see three or more wires, it is a strong sign of a brushless motor.

Operational Characteristics

You can also tell by how the motor acts when it runs. If you spin a brushed motor by hand, you might feel a slight resistance or a "cogging" feeling. This is because of the brushes touching the commutator. If you listen closely to a brushed motor, you might hear a faint scratching or humming sound. This comes from the brushes rubbing. Brushless motors, when spun by hand, feel very smooth. When they run, they are much quieter. They usually make a smooth, low hum. If you have the motor running, pay attention to the sound and smoothness.

Which Type of DC Motor is Best?

There is no single "best" motor for every use. Choosing the wrong type wastes money or gives you bad performance. I will guide you to select the best motor for your specific situation.

The "best" DC motor depends entirely on your application’s specific needs. You must consider cost, lifespan, efficiency, noise, speed control, and required maintenance. Brushed motors are suited for simple, low-cost applications. Brushless motors are better for long-term, high-performance, and precise tasks.

Choosing the right motor is a critical step in any design or repair. It is like picking the right tool for a specific job. You would not use a hammer to drive a screw. Similarly, you would not use a brushed motor for a high-precision, long-life application where a brushless motor would shine. When I worked on a robotic arm project, I had to balance cost with performance. This made me deeply consider each motor’s advantages and disadvantages for specific joints on the arm.

Factors to Consider for Selection

When choosing a DC motor, many factors come into play. Your budget is a major one. Brushed motors are cheaper to buy. However, you also need to think about long-term costs like maintenance. Lifespan is another key factor. If the motor needs to run for many years, a brushless motor is a better choice. Efficiency also matters. Brushless motors save more energy. Noise is important if the motor is for a quiet environment. Speed control precision is vital for applications needing exact movements. Consider how often you are willing to perform maintenance, too.

Common Applications for Brushed Motors

Brushed DC motors are great for many everyday things. They are simple to use and cheap. You often find them in toys, like remote control cars. They are in basic power tools, like drills you use at home. They power small pumps or fans. They are also common in car windows or seat adjusters. For these uses, their lower cost and simpler control circuits make them ideal. They do not need to run constantly or with very high precision. Their occasional maintenance needs are acceptable here.

Common Applications for Brushless Motors

Brushless DC motors are perfect for advanced uses. Their high efficiency and long life make them popular. They are found in drones and other flying machines. They power electric vehicles, from e-bikes to cars. They are in high-end appliances, like modern washing machines. They are also in computer fans, hard drives, and medical equipment. These applications require reliability, precise control, and quiet operation. The higher initial cost is offset by their performance benefits and reduced need for maintenance.

Conclusion

Understanding brushed and brushless DC motors means knowing their design, pros, and cons. Your choice depends on your needs: cost, lifespan, efficiency, and maintenance.