I’ve been in this business for a long time, and I’ve seen countless factories. One time, a new buyer approached us, very excited about a specific stroller design they’d found online. They had all these great ideas for features, colors, and materials. But when we started talking about the actual manufacturing process, they seemed to think it was just a matter of "making it." They were surprised when I laid out the complexities involved – not just assembly, but material preparation, precise component fabrication, and continuous quality checks at every single stage. They had imagined a simple production line, but a stroller, especially one that needs to meet international safety standards, is a complex piece of engineering and textile work. We ended up guiding them through every step, showing them why skipping any stage or cutting corners would compromise not just quality, but critical safety for the baby. It’s never just "making it"; it’s a carefully orchestrated sequence of operations.

Manufacturing a stroller involves precise engineering, material selection, and rigorous testing. It begins with frame fabrication, followed by component assembly, fabric stitching, and final quality checks, ensuring safety and durability for infant transport.

When I saw how many strollers were on the market, I started to wonder: How do they actually make these? It looks like a simple product. But I knew it had to be more complex. Every piece must fit just right. It must be strong enough for daily use. It also must be safe for a baby. This curiosity led me to research the manufacturing process. It is a series of steps. Each step needs careful attention. From raw materials to the final product, there is a lot to consider. Let us look at what goes into making a stroller.

**Here’s an overview of how strollers are typically manufactured:

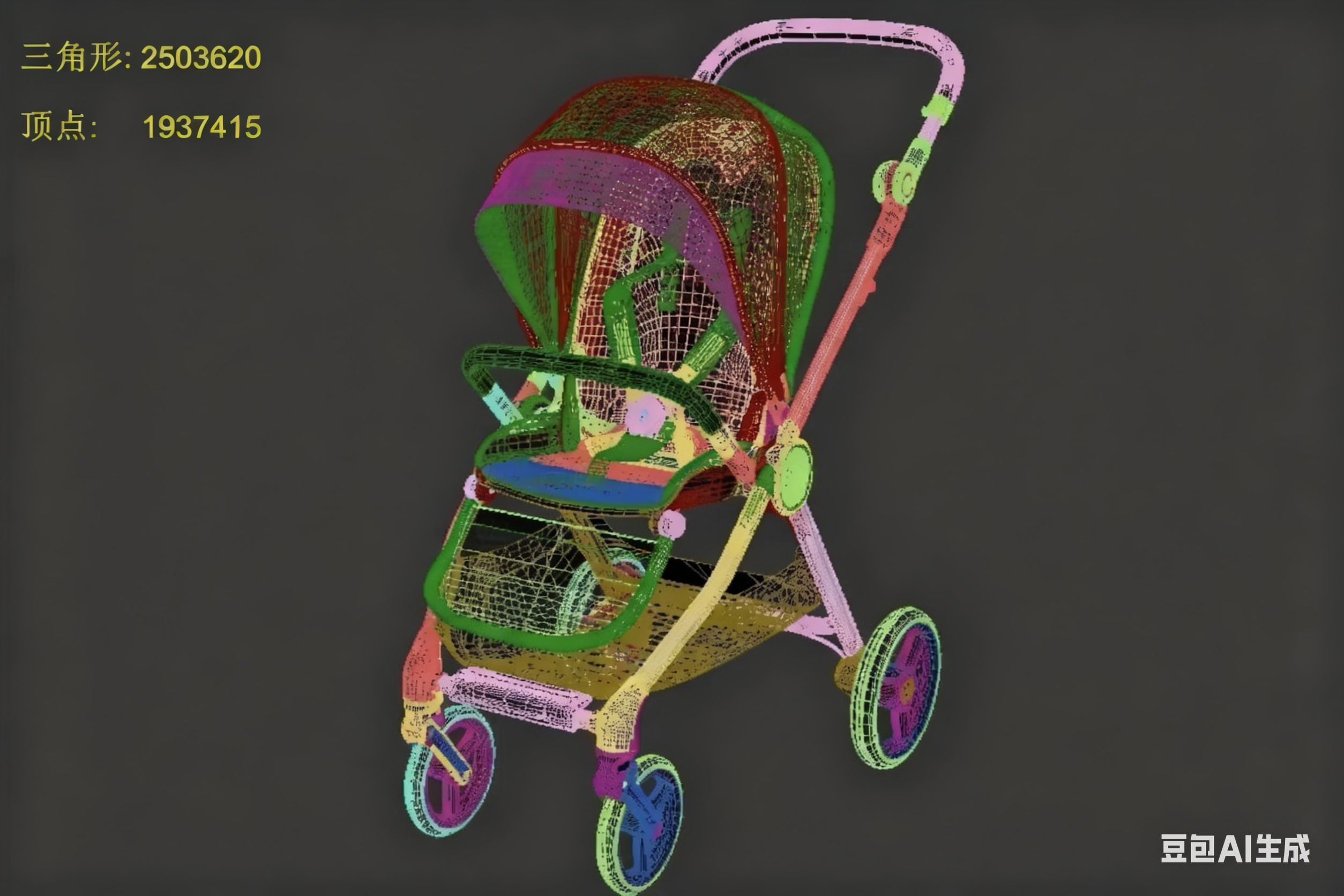

🏭 1. Design and Prototyping

Before manufacturing begins:

Designers and engineers create detailed CAD drawings and prototypes.

Ergonomics, weight limits, safety, and folding mechanisms are tested.

Compliance with standards like EN1888 (Europe) or ASTM F833 (USA) is ensured.

🔩 2. Frame Manufacturing (Metal Parts)

Material: Typically lightweight aluminum alloy or steel tubes.

Processes:

Tube Cutting: Metal tubes are cut to precise lengths.

Bending & Shaping: Tubes are bent using CNC pipe benders to form the frame.

Welding: Joints are welded (manually or robotically).

Surface Treatment: Frames are sandblasted, powder-coated, or anodized to resist corrosion.

🧩 3. Plastic Component Molding

Parts: Wheels, brakes, footrests, handles, clips, etc.

Process:

Injection molding is used to create precise, durable plastic parts from molds.

ABS, PP, and nylon are common materials.

🧵 4. Fabric Production

Materials: Durable, breathable fabrics like polyester or nylon.

Steps:

Fabric is cut using patterns (often with automated cutters).

Sewn into seats, canopies, padding, and storage baskets.

Safety harnesses and zippers are added.

🛠 5. Assembly Line

The stroller is assembled in stages, often in cellular or conveyor-line production:

Frame assembly (attaching wheels, joints, folding mechanisms)

Plastic parts added (handles, trays, etc.)

Fabric installation (seat and canopy attached)

Safety harness installation

Brake and folding mechanism testing

🧪 6. Quality Control & Testing

Every unit undergoes checks:

Structural stability

Brakes and locking mechanism functionality

Folding/unfolding ease

Fabric strength and stitching

Safety compliance testing (e.g., tilt, impact, load)

📦 7. Packaging

The stroller is folded, placed into protective packaging (foam, plastic wrap), then boxed with manuals and accessories.

Barcodes and serial numbers are added for traceability.

What Materials Are Used to Make a Stroller?

Have you ever wondered what a stroller is made of? It is more than just fabric and metal. The right materials ensure safety and durability for your child.

Strollers are primarily made from lightweight metal alloys like aluminum for the frame, durable fabrics such as polyester for the seat and canopy, high-strength plastics for connectors and wheels, and rubber for tires, all chosen for safety, longevity, and ease of use.

I once picked up a very light stroller. Then I picked up a heavier one. I wondered why they felt so different. The difference was often the materials used. Manufacturers choose materials based on many factors. They consider strength, weight, cost, and safety. Each part of the stroller needs different properties. The frame needs to be strong but light. The fabric needs to be comfortable but durable. All materials must meet strict safety standards. They cannot contain harmful chemicals. This careful selection is key to a good stroller.

Frame Materials

Stroller frames commonly use aluminum alloy. This material is very light. It is also very strong. It resists corrosion. Some heavier-duty strollers might use steel. Steel is more durable. It is also heavier. Carbon fiber is used in premium strollers. It is extremely light. It is also very strong. However, it costs much more. The frame provides the main structure. It carries the child’s weight. It connects all other parts. The manufacturing process for frames includes cutting, bending, and welding. Each joint must be strong. It ensures the stroller will not collapse.

Fabric and Plastic Components

The fabrics used in strollers are often polyester. Polyester is durable. It resists fading from the sun. It is easy to clean. Some premium strollers use blends or natural fibers like cotton. Cotton is breathable. But it can be harder to clean. Fabrics are treated to be water-resistant. They also must meet fire safety standards. Plastic parts are used for many smaller components. These include wheels, buckles, connectors, and hinges. Common plastics are polypropylene (PP) and acrylonitrile butadiene styrene (ABS). PP is strong. It is flexible. ABS is very impact-resistant. All plastics must be non-toxic. They must not contain harmful chemicals like phthalates or BPA.

Wheels and Hardware

Stroller wheels vary. Basic strollers often use EVA foam wheels. These are light. They are puncture-proof. But they offer less shock absorption. Higher-end strollers use rubber wheels. Rubber provides better grip. It offers more comfort over bumps. Some have air-filled pneumatic tires. These give the best ride quality. But they can puncture. Hardware includes screws, rivets, pins, and springs. These are typically made of steel or other durable metals. They ensure all parts are securely fastened. They allow for folding mechanisms and braking systems to work. All components work together. They create a safe and functional stroller.

| Material Type | Purpose | Properties | Common Examples |

|---|---|---|---|

| Frame | Structural support | Lightweight, strong, corrosion-resistant | Aluminum alloy, Steel, Carbon fiber |

| Fabric | Seat, canopy, storage | Durable, water-resistant, UV-protected, safe | Polyester, Cotton blends, Nylon |

| Plastics | Connectors, wheels | Impact-resistant, lightweight, non-toxic | Polypropylene (PP), ABS, Nylon |

| Wheels | Mobility, suspension | Durable, shock absorption, puncture-proof | EVA foam, Rubber, Pneumatic tires |

| Hardware | Fasteners, mechanisms | Strong, durable, precise | Steel screws, Rivets, Springs |

What Are the Parts of a Stroller Called?

A stroller seems like a simple way to move a baby. But it has many different parts. Knowing the parts helps you understand how it works.

A stroller consists of key components: a main frame for structure, wheels for movement, a seat or bassinet for the child, a canopy for protection, a handlebar for pushing, a harness system for safety, and brakes for stopping, all working together for function.

When I first bought a stroller, I just saw "a stroller." Then I had to assemble it. That is when I learned it was not just one big piece. It had many distinct parts. Each part has a specific job. If one part is missing or does not work right, the whole stroller might not function well. Or worse, it might not be safe. Learning the names of these parts helps when reading instructions. It also helps when you need to troubleshoot an issue. This knowledge also helps when comparing different stroller models. You can see which features each model offers.

The Core Structure: Frame and Wheels

The frame is the skeleton of the stroller. It is usually made of metal tubing. All other parts attach to it. It provides stability and strength. It determines the stroller’s overall shape. Wheels are essential for movement. Strollers can have three or four wheels. Wheels can be fixed or swivel. Swivel wheels make steering easy. Fixed wheels are good for jogging. Wheels also have a braking system. The brakes are often a foot pedal. They lock the wheels in place. This prevents the stroller from rolling away. A good braking system is critical for safety.

Child Containment: Seat, Harness, and Canopy

The seat is where the child sits. It can recline for naps. Some strollers come with a bassinet. This is for newborns. It allows them to lie flat. A harness system secures the child in the seat. This is usually a 3-point or 5-point harness. The 5-point harness secures at the shoulders, hips, and between the legs. This is the safest option. The buckle connects the harness. It must be easy for an adult to open. It must be hard for a child to open. The canopy or hood protects the child. It shields them from sun, wind, and light rain. Many canopies have a peek-a-boo window.

Control and Convenience: Handlebar and Accessories

The handlebar is what you use to push the stroller. It can be adjustable in height. This makes it comfortable for different users. Some strollers have a reversible handlebar. This allows the parent to face the child. A storage basket is typically found under the seat. It holds diapers, bags, and other items. The folding mechanism allows the stroller to collapse for storage or transport. This usually involves latches and buttons. It should be easy to use. Some strollers come with additional accessories. These include cup holders, footmuffs, or rain covers. Each part plays a role in the stroller’s overall function and safety.

| Part Name | Function | Key Features / Considerations |

|---|---|---|

| Frame | Provides structural support | Material (aluminum, steel), folding type |

| Wheels | Enables movement, provides stability | Number of wheels, material (EVA, rubber), swivel vs. fixed, suspension |

| Seat / Bassinet | Holds the child comfortably | Recline positions, padding, fabric type |

| Canopy | Protects child from elements | Extendability, UV protection, peek-a-boo window |

| Handlebar | For pushing and steering | Adjustable height, ergonomic design, reversible |

| Harness System | Secures child in seat | 3-point or 5-point, buckle safety |

| Brakes | Stops and locks the stroller | Foot-operated, hand-operated, ease of use |

| Storage Basket | Holds personal items | Size, accessibility, weight capacity |

| Folding Mechanism | Allows compact storage | One-hand fold, compact size, latching system |

Why Are Strollers So Expensive?

Looking at stroller prices can really shock you. Why do some cost so much more than others? Understanding the factors explains the cost.

Strollers are expensive due to the high cost of quality and safe materials, extensive safety testing and certifications, significant research and development for innovative features, complex manufacturing processes, brand reputation, and additional features like advanced suspension or modularity.

I remember looking at a stroller and seeing a price tag that made my jaw drop. I thought, "It is just a baby carrier on wheels, right?" But then I started to think more deeply about it. This is a product that holds my most precious cargo. It needs to be incredibly safe. It needs to be durable. It must last through many adventures. It must meet many safety rules. These are not simple toys. They are complex pieces of equipment. There are many hidden costs that contribute to that price tag. It is not just about the materials you see.

Material Quality and Safety Testing

High-quality materials cost more. Strollers use aviation-grade aluminum for lightweight frames. They use premium fabrics that are durable, water-resistant, and free from harmful chemicals. These materials are more expensive than standard ones. Beyond material cost, safety testing is a huge factor. Strollers undergo rigorous third-party testing. These tests check for structural integrity. They check for stability. They check for chemical safety. They check for choking hazards. Each test costs money. Getting certifications in different countries also adds to the cost. Manufacturers spend a lot to ensure the stroller meets global safety standards. This process ensures the product is safe enough for a baby.

Research, Development, and Manufacturing

The design process itself is expensive. Companies invest heavily in research and development (R&D). This includes market research. It includes engineering. It includes prototyping. They work to create new features. They work to improve existing designs. Think about advanced suspension systems. Think about one-hand folding mechanisms. These innovations require a lot of engineering talent and time. The manufacturing process is also complex. It involves precision cutting, welding, stitching, and assembly. Quality control checks are done at every stage. This ensures consistency and safety. This meticulous process adds to the labor costs. It adds to the overhead.

Brand, Features, and Market Factors

Brand reputation plays a big role. Established brands often charge more. They have a history of reliability. They have strong customer support. Marketing and distribution costs also add up. This includes advertising. It includes shipping to retailers. Features also drive up the price. A basic stroller has fewer features. A high-end stroller has many options. These include adjustable handlebars, reversible seats, large storage, car seat compatibility, and multi-terrain wheels. Each added feature increases the complexity. It increases the material cost. It increases the manufacturing time. All these factors contribute to the final price consumers pay.

| Cost Factor | Impact on Price | Example |

|---|---|---|

| Material Quality | Higher cost for premium, durable, safe materials | Aviation-grade aluminum, organic fabrics |

| Safety Testing | Required for certifications, extensive lab tests | Chemical tests, stability tests, durability tests |

| Research & Development | Innovation, design, engineering of new features | One-hand fold, advanced suspension systems |

| Manufacturing Complexity | Precision assembly, strict quality control | Robotic welding, detailed stitching, multi-stage QC |

| Brand & Marketing | Reputation, advertising, customer service | Premium brand recognition, global distribution |

| Features & Accessories | Added functionality, modularity, customization | Reversible seat, car seat adapters, weather shields |

Conclusion

Manufacturing a stroller involves choosing strong, safe materials and assembling many precise parts. High costs come from quality materials, rigorous testing, and complex design.