When sourcing high chairs internationally, safety standards are not just a compliance issue — they directly affect product liability, market access, and long-term brand trust. Among all global standards, EN 14988 (Europe) and ASTM F404 (United States) are the two most influential and most frequently requested by buyers, retailers, and regulators.

In simple terms, EN 14988 focuses more on structural stability, entrapment risks, and long-term durability, while ASTM F404 places stronger emphasis on real-world misuse scenarios, labeling, and consumer behavior. Serious buyers should understand both, even if selling in only one market.

| Standard | Main Market | Core Focus | Buyer Risk If Ignored |

|---|---|---|---|

| EN 14988 | EU / UK | Stability, entrapment, structural safety | Customs rejection, CE non-compliance |

| ASTM F404 | USA / Canada | Misuse prevention, labeling, tip-over scenarios | Recall, CPSC penalties |

| Both | Global brands | Full safety coverage | Brand & legal exposure |

Article updated: January 17, 2026

What Is EN 14988?

EN 14988 is the European safety standard for high chairs, required for CE marking when selling in the EU and UK.

It applies to:

- High chairs

- Reclining high chairs

- Convertible high chair systems

Key Safety Areas Covered by EN 14988

EN 14988 places strong technical emphasis on passive safety, meaning the chair should remain safe even with minimal user intervention.

Main test categories include:

- Static stability (forward, backward, sideways)

- Structural strength and fatigue testing

- Entrapment hazards (head, fingers, limbs)

- Harness system effectiveness

- Footrest and seat integrity

A major characteristic of EN 14988 is dimensional precision — exact gap sizes, angles, and load positions are strictly defined.

What Is ASTM F404?

ASTM F404 is the mandatory U.S. consumer safety standard for high chairs, enforced through the Consumer Product Safety Commission (CPSC).

Unlike EN 14988, ASTM F404 strongly reflects real-life usage and misuse patterns observed in American households.

Key Safety Areas Covered by ASTM F404

ASTM F404 focuses on:

- Tip-over resistance during movement

- Tray push and pull forces

- Standing and climbing scenarios

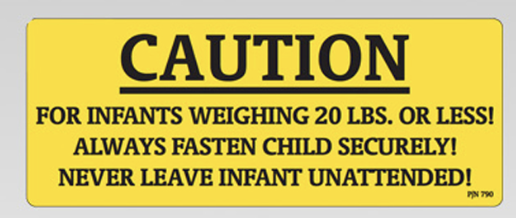

- Warning labels and instructions

- Realistic dynamic loading

ASTM assumes:

“Parents may not use the product perfectly.”

This makes misuse testing and warnings much more prominent.

EN 14988 vs ASTM F404: Core Differences That Matter to Buyers

| Aspect | EN 14988 | ASTM F404 |

|---|---|---|

| Stability testing | Static & controlled | Dynamic & misuse-based |

| Entrapment focus | Very strict | Moderate |

| Labeling | Required but limited | Very detailed |

| Tray testing | Strength & lock | Push-pull & misuse |

| Consumer behavior | Assumes correct use | Assumes incorrect use |

| Legal exposure | Customs & CE | Recall & lawsuits |

This is why a product passing only one standard is often not enough for global buyers.

Stability Testing: Why the Results Can Differ

It is common for a chair to:

- Pass EN 14988

- Fail ASTM F404

This usually happens because:

- EN focuses on center-of-mass stability

- ASTM applies forward force, side force, and simulated child movement

For B2B buyers, this is a critical insight:

A “CE-approved” chair is not automatically “US-safe”.

Harness and Restraint System Comparison

EN 14988:

- Focuses on strength and durability

- Requires defined load resistance

ASTM F404:

- Focuses on effectiveness during misuse

- Strong emphasis on preventing standing and climbing

This difference directly impacts tip-over risk in real homes.

Weight Limits and Age Scope Differences

EN 14988:

- Clearly defines maximum child weight

- Emphasizes structural limits

ASTM F404:

- Links weight limits with behavioral risk

- Requires clearer consumer warnings

This is why U.S. recalls often involve “continued use beyond recommended age”.

Which Standard Is “Stricter”?

This is a common buyer question — and the honest answer is:

They are strict in different ways.

- EN 14988 is stricter in engineering precision

- ASTM F404 is stricter in real-world safety enforcement

For professional buyers, dual compliance is the safest long-term strategy.

What Smart Buyers Do Before Placing Orders

Experienced importers and retailers usually:

- Design products to meet both standards

- Test samples against EN + ASTM early

- Avoid “market-specific” shortcuts

- Review past recall cases before final approval

This reduces:

- Re-testing costs

- Recall probability

- Insurance premiums

- Legal exposure

How This Article Connects to the High Chair Safety Hub

This page is a core authority node, linking directly to:

- Why High Chairs Tip Over (And How to Prevent It)

- High Chair Weight Limits and Stability Testing Explained

- High Chair Recall Reasons and How Buyers Can Avoid Them

- Wood vs Plastic High Chairs: Safety and Durability Comparison

Together, they form a complete buyer-oriented safety knowledge cluster.

Final Takeaway for B2B Buyers

If you are sourcing high chairs internationally, understanding EN 14988 vs ASTM F404 is not optional.

The brands that survive long-term are the ones that:

- Design beyond minimum compliance

- Anticipate misuse

- Build safety into structure, not marketing

Standards are not paperwork — they are risk management tools.

Written by Sherry, Baby Product Sourcing Manager with 15+ years of experience in stroller and high chair supply chains, working with supermarkets and distributors worldwide.